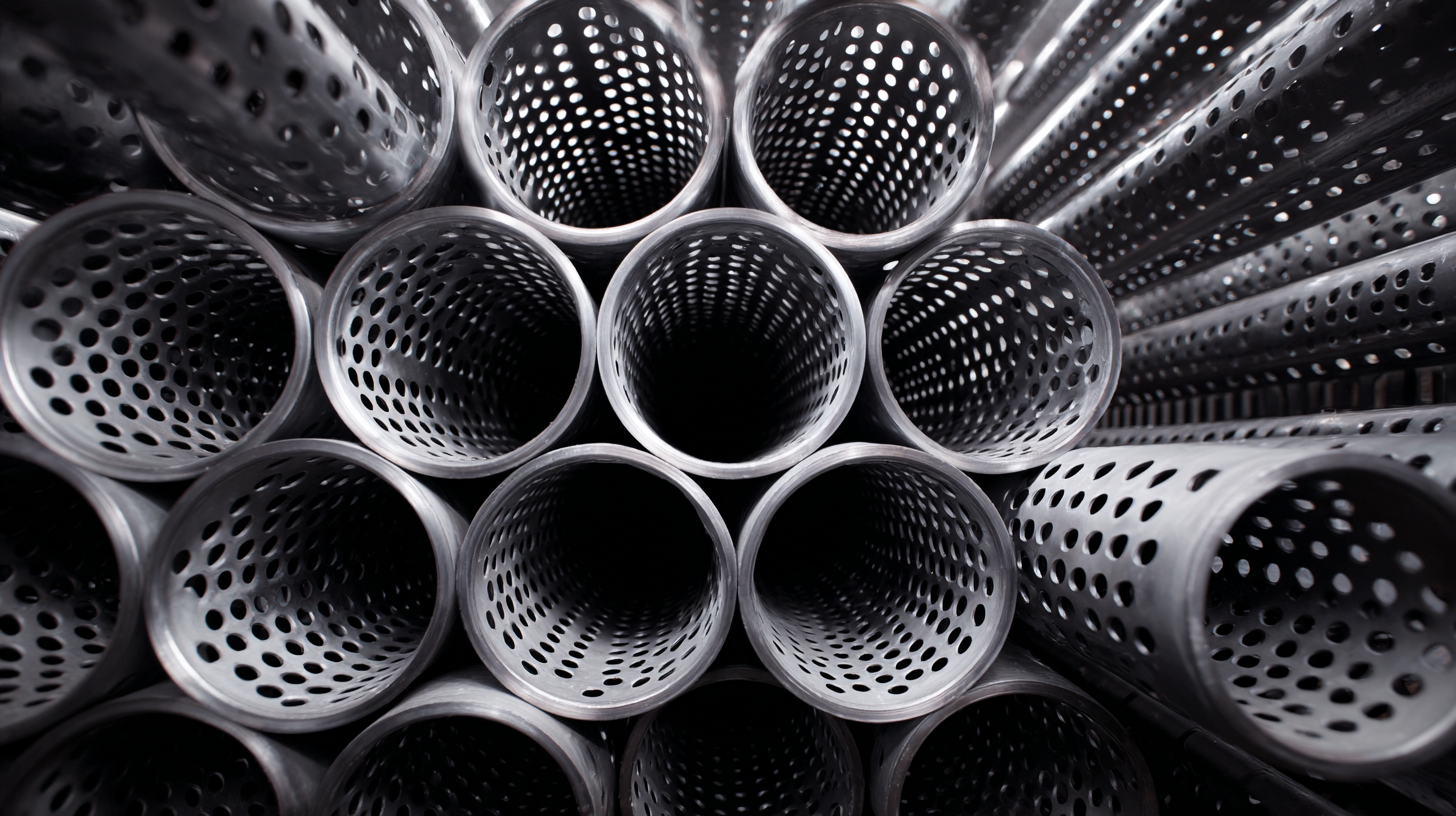

The proper installation and optimization of perforated pipes are crucial for various applications, including drainage systems, sewage management, and agricultural irrigation. According to the American Society of Civil Engineers, approximately 50% of urban runoff is managed using effective drainage solutions, where perforated pipes play a significant role. By allowing water to flow into or out of the surrounding soil, these pipes contribute greatly to reducing environmental impact and preventing flooding.

A recent industry report highlighted that properly designed perforated pipe systems can improve drainage efficiency by up to 30%, showcasing their importance in Smart Water Management strategies. As the demand for efficient water management solutions increases, optimizing perforated pipe installations becomes essential for maximizing performance and sustainability.

This blog will explore effective strategies to enhance the efficiency of perforated pipe installations, ensuring they meet both current and future environmental needs.

When it comes to optimizing your perforated pipe installations, understanding the placement and flow dynamics is crucial for achieving maximum efficiency. Proper placement of perforated pipes allows for effective drainage and consistent water management, reducing the risks of water accumulation and potential damage to your landscape and infrastructure. Whether it’s for agricultural fields or residential areas, the positioning of these pipes significantly influences their functionality and the overall performance of your drainage system.

Recent advancements in irrigation and drainage practices highlight the need for strategic planning in the installation of perforated pipes. For instance, integrating these systems with seasonal water management techniques can enhance their capacity to handle varying water levels. By observing current trends and case studies, such as the expansion of drainage services tailored to seasonal challenges, installers can adopt best practices that not only improve efficiency but also address potential environmental impacts, including water quality preservation.

| Dimension | Recommended Value | Impact on Efficiency |

|---|---|---|

| Pipe Diameter (inches) | 4 | Increased water flow capacity |

| Perforation Size (mm) | 10 | Enhanced drainage performance |

| Spacing Between Pipes (feet) | 20 | Optimized soil saturation |

| Installation Depth (feet) | 3 | Balanced groundwater interaction |

| Material Type | PVC | Durability and corrosion resistance |

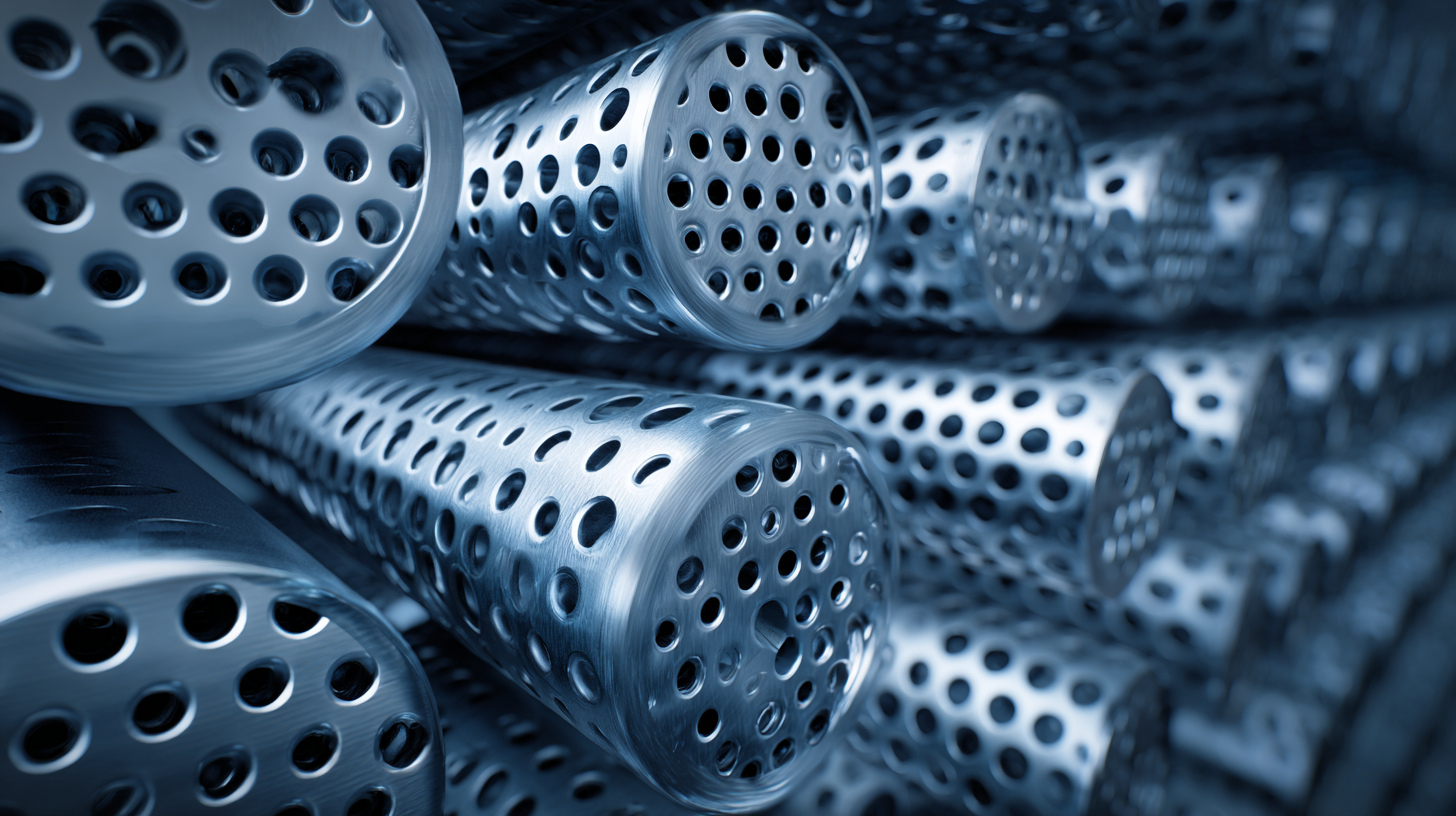

Selecting the right perforated pipe material is crucial for optimizing installation efficiency and ensuring long-term performance. According to a recent industry report by the American Society of Civil Engineers (ASCE), the correct choice of materials can reduce maintenance costs by up to 30%. When considering material options, factors such as strength, durability, and corrosion resistance should be prioritized. For instance, PVC pipes are widely praised for their resistance to decay, making them ideal for environments where moisture is a concern, while HDPE pipes offer high tensile strength and flexibility, useful in fluctuating soil conditions.

Another significant consideration is the perforation pattern and size, which greatly affects fluid dynamics. Studies indicate that a well-designed perforation layout can enhance water flow by as much as 25%, reducing pressure loss and increasing system efficiency. Additionally, applying industry standards such as ASTM F794 can guide the selection process, ensuring materials meet performance criteria suitable for various applications, from agricultural drainage to stormwater management. By leveraging these strategies, professionals can maximize their installations' effectiveness while minimizing costly repairs and replacements over time.

When optimizing perforated pipe installations, several key factors contribute significantly to flow efficiency. According to recent industry analysis, the global perforated pipe market is expected to grow substantially, impacting various sectors such as agriculture, drainage, and construction. Ensuring proper alignment and spacing of the pipes can enhance fluid dynamics, leading to improved flow rates and reduced clogging.

When optimizing perforated pipe installations, several key factors contribute significantly to flow efficiency. According to recent industry analysis, the global perforated pipe market is expected to grow substantially, impacting various sectors such as agriculture, drainage, and construction. Ensuring proper alignment and spacing of the pipes can enhance fluid dynamics, leading to improved flow rates and reduced clogging.

Tip 1: Ensure that the perforation size and pattern are designed according to the specific application, as this can dramatically affect the flow characteristics and overall efficiency of the system.

Another crucial consideration is the material used for the pipes. High-quality materials not only resist corrosion but also ensure longevity, reducing maintenance costs over time. The integration of advanced technologies, such as AI and CAE, further enables precise modeling and simulation of fluid dynamics, thereby optimizing the installation process.

Tip 2: Regularly inspect and maintain your perforated pipes to ensure that any blockages or degradations are identified early. This proactive approach can prevent costly downtime and improve overall system performance.

In conclusion, understanding these key factors and incorporating the latest technologies will ensure that your perforated pipe systems operate at maximum efficiency, ultimately leading to reduced operational costs and better resource management.

When installing perforated pipes, understanding varying soil conditions is crucial for ensuring optimal drainage efficiency. According to the American Society of Civil Engineers (ASCE), improper installation can lead to significant issues, including soil erosion and reduced water filtration. To achieve maximum efficiency, installers should focus on three best practices tailored to specific soil types.

First, when dealing with clay soils, which are often dense and impermeable, it is essential to ensure proper backfilling around the perforated pipes. Studies published in the Journal of Soil and Water Conservation suggest that incorporating coarse aggregates during backfilling can greatly improve water flow, enhancing the system's ability to manage excess moisture.

Second, in sandy soils, the primary concern is stability and potential displacement. The National Drainage Association recommends using geotextiles to wrap perforated pipes, which prevents soil migration while maintaining water permeability. This approach not only bolsters the integrity of the installation but also extends the lifespan of the drainage system.

Lastly, for loamy soils, a careful balance of soil compaction is vital; research from the Soil Science Society of America indicates that slight compaction around the pipes can optimize drainage performance while minimizing sediment buildup. Each soil condition demands a unique approach, and adherence to these best practices can significantly elevate the efficiency of perforated pipe installations.

Regular maintenance is crucial for enhancing the performance of perforated pipes, a key component in drainage and irrigation systems. According to a study by the American Society of Civil Engineers, improperly maintained drainage systems can reduce water flow efficiency by up to 30%. Regular inspections can identify clogs, corrosion, and other issues that might hinder performance. By implementing scheduled maintenance, operators can significantly prolong the lifespan of these systems and maintain their efficiency.

Furthermore, a report from the Water Environment Federation emphasizes the importance of cleaning and flushing perforated pipes regularly. This practice can improve infiltration rates and prevent sediments from accumulating, which can otherwise lead to costly repairs. The study indicates that facilities that adhered to a rigorous maintenance schedule experienced an improved flow rate of approximately 40%. By investing in regular maintenance, businesses not only enhance system functionality but also ensure compliance with environmental regulations, thus avoiding potential fines and penalties associated with inefficient water management.